Reverse osmosis industrial type from 15 mc / h with food tank.

Reverse Osmosis

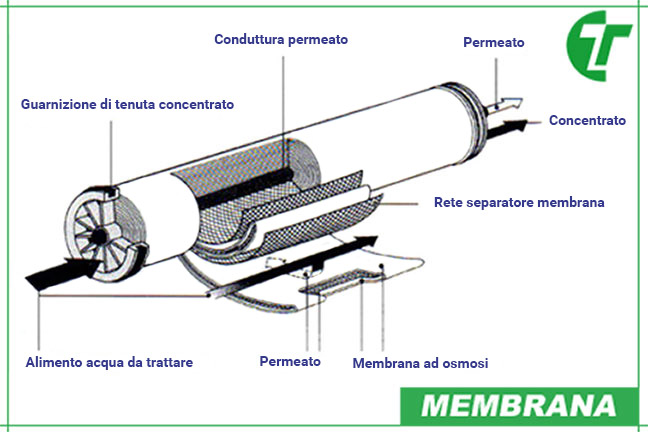

Osmosis is a natural process by means of which, between two solutions with different salt concentration, separated by a semipermeable membrane, the water tends to pass from the most diluted to the most concentrated one. Instead, reverse osmosis is a a process which separates foreign matters from water using semipermeable membranes which allow water flow, detaining salts, bacteria and colloids.

This process is carried out by applying to the concentrated solution a pressure higher than the osmotic pressure, enabling a reverse flow through the membrane, thus separating the salts from water. The semipermeable membranes used by Tecnocom let the water pass detaining 99-99.7% of the Ions contained in it.

Images

Unlike other kinds of process, where all the water passes through the filter, which in a short time reaches saturation, requiring cartridge replacement, reverse osmosis enables a “tangential” passage, obtaining two different flows exiting the system:

- the “concentrate”, containing impurities which, not passing through the membrane, are repelled;

- the“permeate” which is the result of the treatment.

The concentrate continuously cleans the membranes, ensuring long operation of the equipment before requiring an actual cleaning. It can be sent to the discharge, in compliance with the applicable standards, or can be used for other applications where low salinity water is not required.

Drawbacks

The only potential drawback, even for a reverse osmosis equipment using high quality parts such as the one realized by Tecnocom, is inactivity: until the flow across the membranes is constant, the cleaning action performed by the concentrate keeps them clean; when this flow stops the impurities tend to deposit on the filtering surface, decreasing its efficiency. This is typical of any reverse osmosis system; for this reason Tecnocom has designed a low pressure “flushing” system which, when the system is switched off, automatically cleans it to remove the high salinity water contained inside.

Two Configurations

The equipment manufactured by Tecnocom is fully autonomous, it requires just the power to supply the pumps and is realized in two different configurations:

- model ROT SR, basic version

- model ROT, version provided with low pressure flushing system, tank ebd electric panel PLC

Plant for sterilization hospital: ROT DS models are reverse osmosis systems in dual stage conforming to EN 285, the system ensures conductivity less than 5 microsiemens and storage of water parameters sent to the user.